Hi Guys

I haven't used the TBird for a few weeks so went to fire it up today & go cruising but it was a "no go".

Motor turns as usual but no spark.

I had a local mobile auto electrician call in & check for faults.

His diagnosis was that the coil was the problem, power to it but nothing out.

On his advice, I purchased & fitted a new coil but still no spark.

Put a plug lead on an old spark plug & the body to ground while turning the engine over....nothing.

Points are opening & closing & correct setting.

Is my next step to replace the condenser???

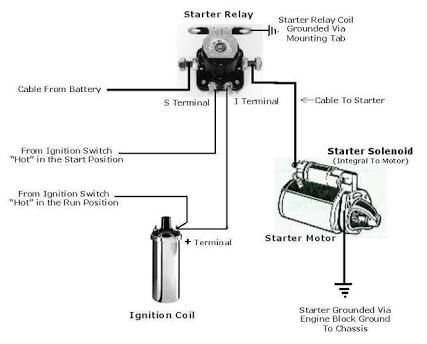

Could it be a problem with the coil resistor???

Also, where is the coil resistor located????

Not being at all an electrical person, any advice will be greatly appreciated.

Thanks guys

Lex

I haven't used the TBird for a few weeks so went to fire it up today & go cruising but it was a "no go".

Motor turns as usual but no spark.

I had a local mobile auto electrician call in & check for faults.

His diagnosis was that the coil was the problem, power to it but nothing out.

On his advice, I purchased & fitted a new coil but still no spark.

Put a plug lead on an old spark plug & the body to ground while turning the engine over....nothing.

Points are opening & closing & correct setting.

Is my next step to replace the condenser???

Could it be a problem with the coil resistor???

Also, where is the coil resistor located????

Not being at all an electrical person, any advice will be greatly appreciated.

Thanks guys

Lex

Comment