Some nice parts there Dave ...

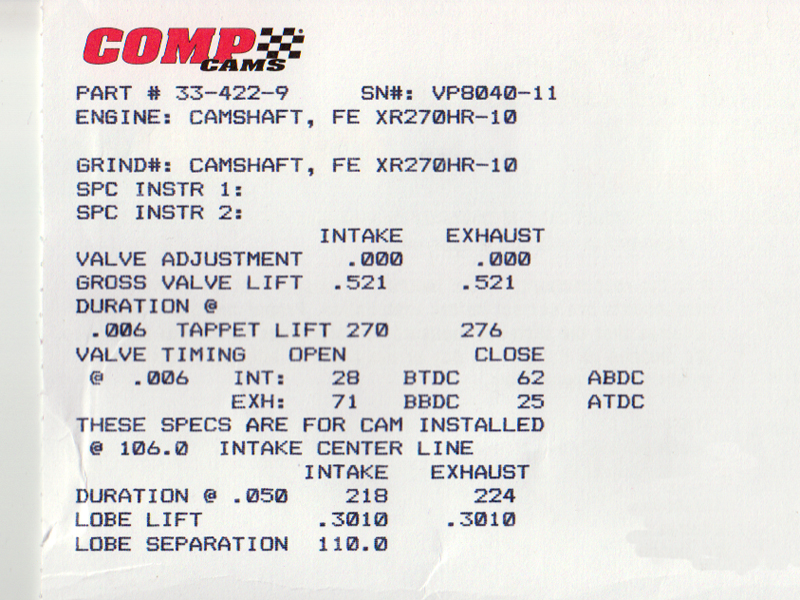

could you list your came specs? The stock Edelbrock springs may be marginal for your hyd. roller with the quicker ramps they tend to have. Mike

could you list your came specs? The stock Edelbrock springs may be marginal for your hyd. roller with the quicker ramps they tend to have. Mike

Comment