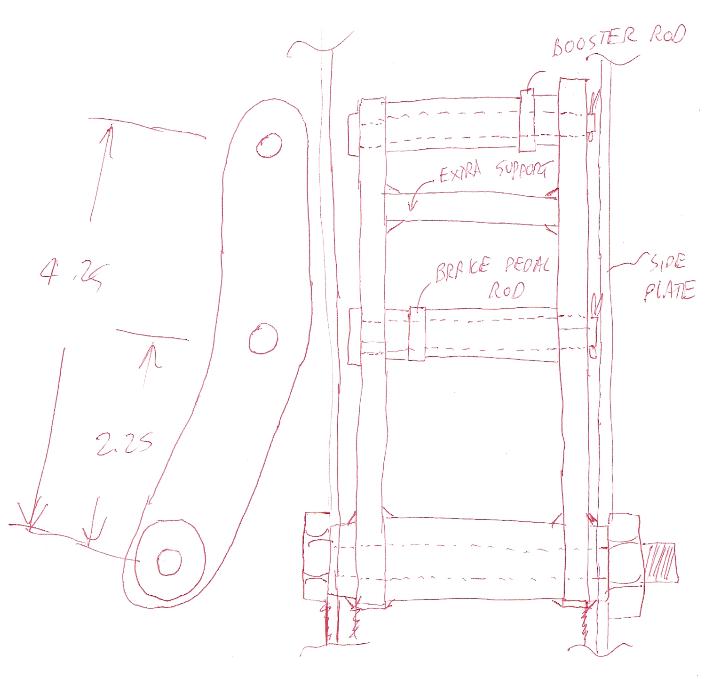

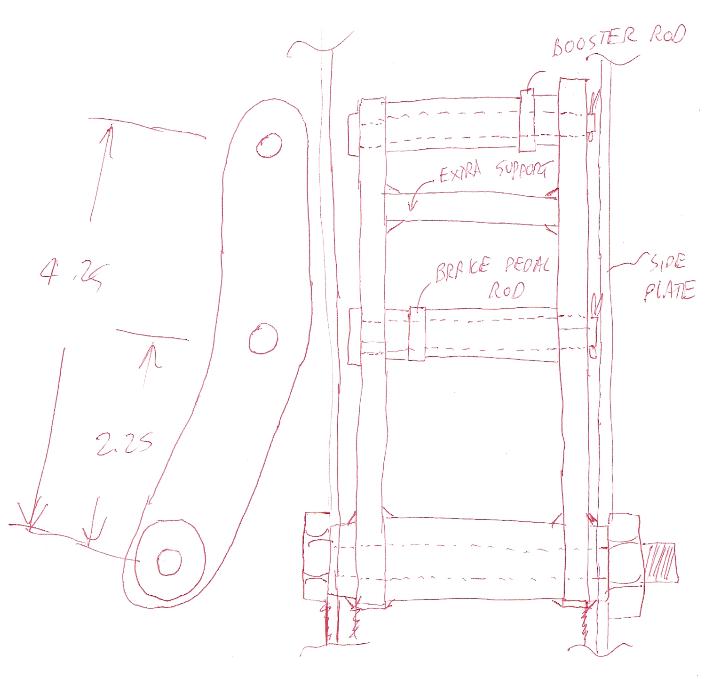

Had a different idea for the fulcrum

setup last night. Drew up a quick sketch.

This would sort of, put both pedal and

booster rods in double shear, and should

strengthen the entire setup.

Hope to get this mostly knocked out

this weekend...........

setup last night. Drew up a quick sketch.

This would sort of, put both pedal and

booster rods in double shear, and should

strengthen the entire setup.

Hope to get this mostly knocked out

this weekend...........

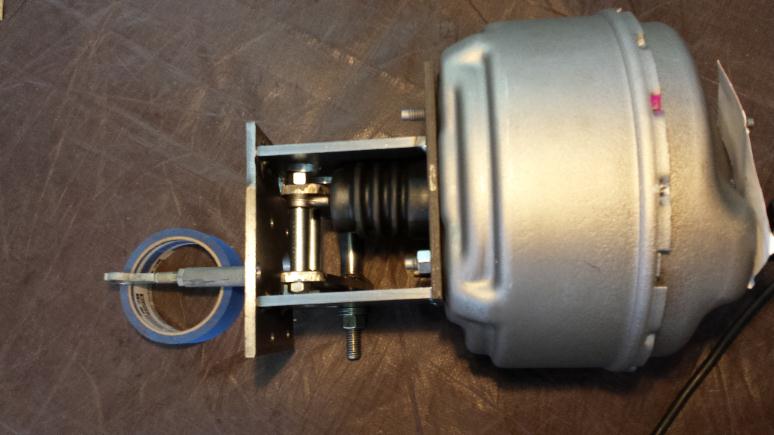

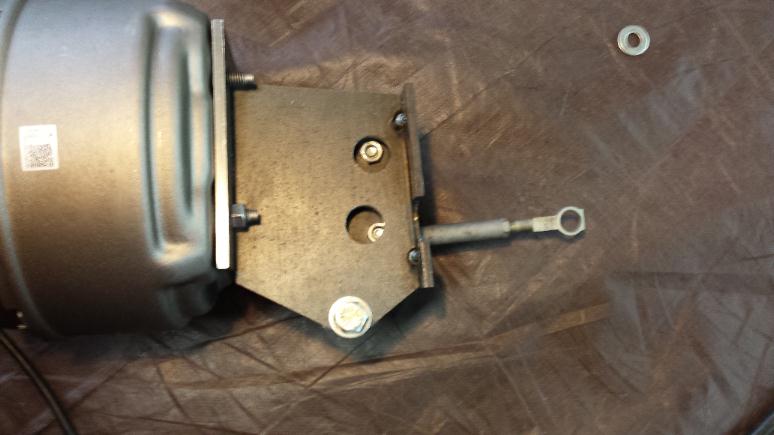

Oh brother was I ever dreaming.

Oh brother was I ever dreaming.

Comment