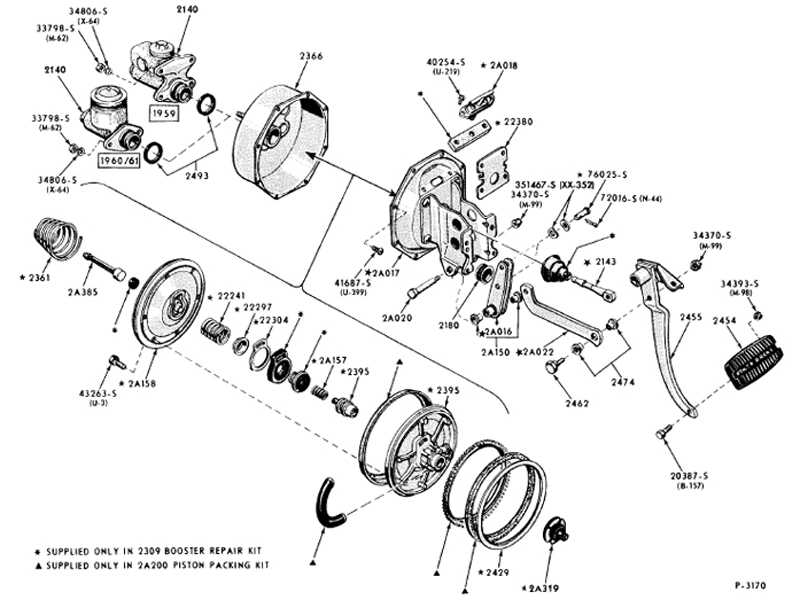

Decide I had better look at a brake problem that I have had since last year (don't want to be to hasty). After removing the master cylinder I found that the booster unit was full of brake fluid so I started to remove it. It says in the manual to remove the 4 bracket to dash panel retaining nuts and washers. Are these the same nuts that are holding the rear of the pedal support bracket and what is the best way to remove them and put them back afterwards?

Cheers

Phil

Cheers

Phil

Comment